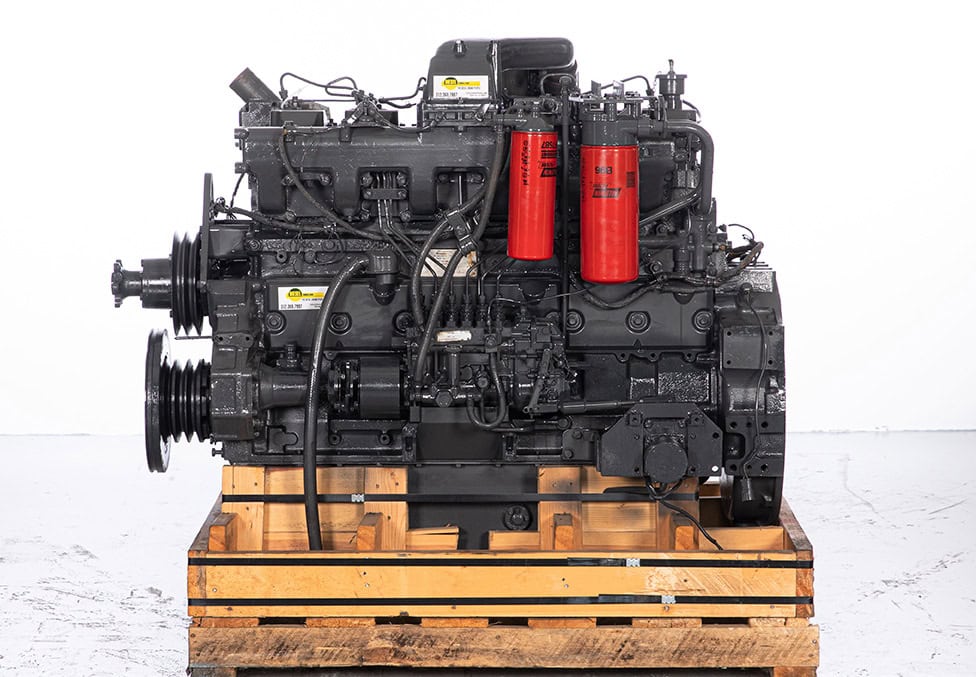

Remanufacturing Diesel Engines

We specialize in remanufacturing off-road diesel engines. We also supply most remanufactured on-highway diesel engines for trucks. After being machined, our professionally trained engine technicians take an engine core and rebuild it from the ground up.

See our remanufacturing process here.

Remanufacturing a diesel engine is often a great alternative to purchasing a new engine. Remanufacturing your engine allows us to build a complete drop-in for you. This reduces your labor costs to install and ensures a perfect fit. Remanufacturing is more cost-effective. Dyno testing our remanufactured engines begins the break-in process. Once installed, it is ready to go to work.