OUR AIM AT BEING ECO FRIENDLY

We strive to do anything we can to be more sustainable.

One of our priorities is to reduce our waste and negative impact on the environment.

We strive to do anything we can to be more sustainable. Here is how:

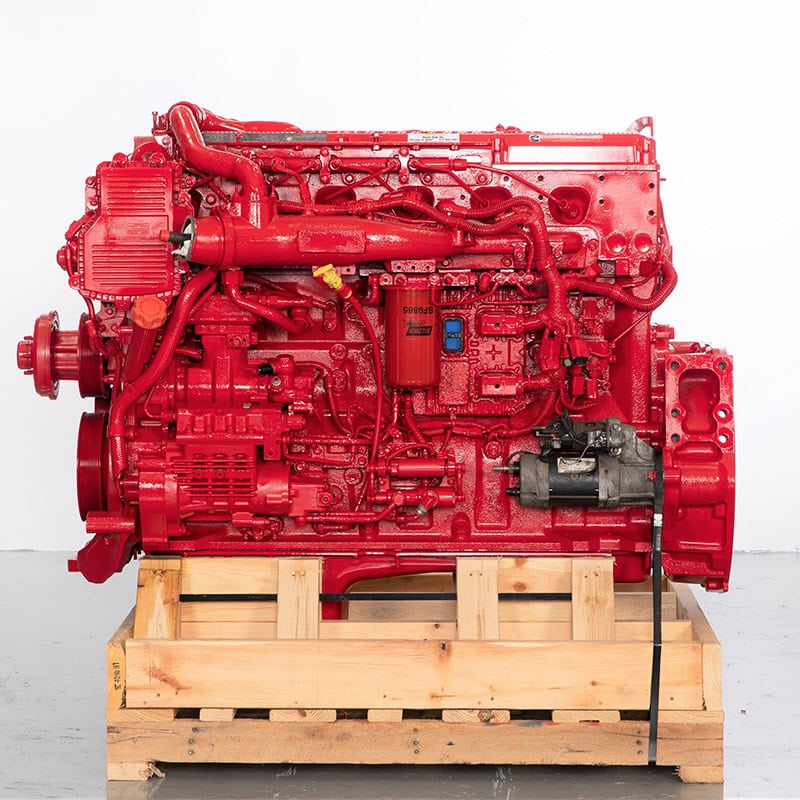

REMANUFACTURING DIESEL ENGINES

Our engine remanufacturing department operates 6 days a week. Our trained engine technicians completely transform engine cores with new or remanufactured parts that meet or exceed OEM specifications.

In addition to the low out-of-pocket costs and fitting exactly to specifications, another benefit to buying a Diesel Sales remanufactured engine is that it is better for the environment!

CONSERVING ENERGY

Oftentimes, unused diesel engines are scraped and melted down in a process called smelting.

By remanufacturing, we eliminate the smelting process and reduce air pollution.

REDUCING LANDFILL SPACE

Remanufacturing your diesel engine keeps parts out of landfills, scrap facilities and lumber facilities. We machine all engine parts upon arrival.

After all parts are cleaned and inspected, we are able to determine what parts may be reused in the remanufacturing process.

CONSERVES RAW MATERIALS

Remanufacturing a diesel engine allows for the recycling of parts once they are machined.

This reduces the need for new, raw materials, such as copper and aluminum.

WATER FILTRATION SYSTEM

At Diesel Sales, we power wash our product to ensure no grease or dirt is left behind. Our power washing is all done in an area specifically designed to collect all waste, oil and dirt from the engine. The waste that comes off of the engine is pumped into an oil and water separating system.

Once the water and oil are separated, the water is pumped through a filtering system that captures any remaining oil or waste, allowing clean water to filter to our garden located behind our warehouse. This garden attracts pollinators of all kinds from the surrounding community. The discarded oil is recycled every three months with our recycling service.

LED LIGHTS

At Diesel Sales, our remanufactured engines require precision work. To help our engine technicians complete their work and produce top-quality engines, we have upgraded our fluorescent lights to LED lights. This reduces our energy consumption by 80%!

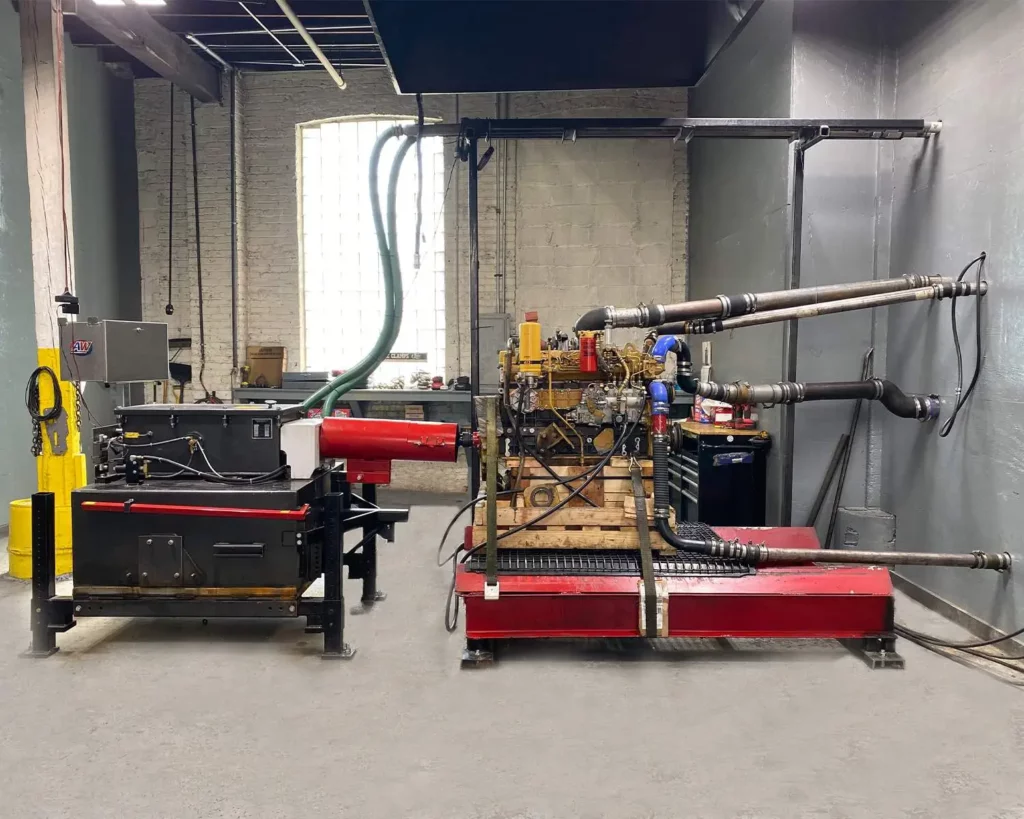

OUR DYNO

Our Dyno is a self-contained system. We built a system for our dyno to reuse the water needed to cool down the engines. This saves on water usage. This system is stored in a 800-gallon water storage tank.

we keep honeybees!

We have a bee hive on top our warehouse that yields delicious honey and supports our local bee population!

GIVE US A CALL FOR A QUOTE!

Have your make, model, engine, transmission, or part number ready and we will give you a quote!